HCL TANK Sampling, PLASTIC PVC SAMPLERS

For Hydrochloric acid HCL tanks in Pickling plants we offer liquid bottle samplers made of plastic PVC or PP.

In pickling plants we are looking for safer and better ways to take samples of the large acid tanks for pickling, HCL rinsing and phos rinsing.

These plastic tanks are installed with flange connections

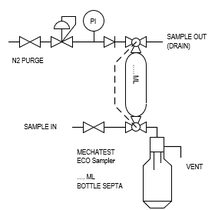

Manual sampling can be much safer and Mechatest designed a plastic PVC (or PP) back purge sampler for taking these HCL acid liquid samples, the Back Purge configuration flush the HCL sample back before sampling, suitable to get representative sample in case a bypass (circulation) flow is not present. This bottle sampler is a combination of a 3-way valve, liquid bottle sampler and compressed air back purge system.

The liquid sampler can take spot samples in pickling, HCL rinsing and phos rinsing liquid applications under atmospheric pressure. This typical

“needle” bottle sampler is closed loop and suitable for emission free sampling of toxic, dangerous HCL acids or volatile liquids.

Hydrochloric acid is an important and widely used chemical. The largest end uses for hydrochloric acid are steel pickling, oil well acidizing, food manufacturing, producing calcium chloride, and

ore processing.

HCL sample wiki

Hydrochloric acid (HCL) is the simplest chlorine-based acid system containing water. It is a solution of hydrogen chloride and water, and a variety of other chemical species, including hydronium and chloride ions. HCL, is an aqueous solution of hydrogen chloride gas, mostly produced by the chlorination of organic chemicals; the combination of hydrogen and chlorine.

- Main hazards; highly corrosive and hazardous, strongly acidic

- Viscosity; 1.1 - >2 cP (25 °C)

- Vapor pressure; 0.02 - 0.28 bar (25 °C)

- Density; 1.0 - 1.2 (20) g/cm3

- Explosive limits; n/a

Representative and Safe Sampling of HCL Liquid

The big advantage of the PVC or PP HCL sampling system is the possibility to take safely a Hydrochloric acid (HCL) liquid sample under extreme highly corrosive and strongly acidic processes and fill it into a glass sample bottle, the sample is directly take from a tank, container, pipeline, reactors or mixer. We have improved our HCL sampling systems for liquids by:

- Creating closed loop systems emission free which provide a safe, controlled environment

- Suitable for high pressure process application

- Adding sample (needle or process) purge options with Nitrogen or other gas

- Fixed volume sampling, which minimizes both waste and costs

- Simplifying designs, making the sampling of liquid and gas more efficient

- Proper discharge of excess liquid or gas prevents unwanted pressure build-up in the system

These modern solutions simply regard the sampling systems themselves. Our worldwide reputation rests on the combination of excellent systems, and professional services by our team of specialists.

Enjoy the full benefits of an experienced team of passionate professionals

Mechatest employees possess decades of experience and knowledge. All of which is at your disposal when your sampling system needs adaptations, maintenance or repairs. Our staff has high-tech equipment at their disposal, thus increasing their efficiency even more. We are even capable of designing and manufacturing in accordance with foreign codes and standards.

Start improving by sampling process today

Why wait any longer? Improvement starts today if you pick up the phone and call us at +31 (0)15 – 310 51 83. Our staff provides you with all the information you need to make an informed decision and choose the best sampling systems for liquid or liquefied gas.

Also view

sample bottle choices | bottle sampler configurations | lab sampling | sampler request form | guide to select the best sampler | needle purge sampler | polyester housings | sentry sample cooler | spot sampling

Contact us

Be part of the best solution, it all starts with you!

We make sampling solutions helping to protect the environment now and for future generations, together we can make a difference.

| Doedijns - Mechatest Sampling Solutions | Vydraulics Group | Vremac | Sypack | |

| Bleiswijkseweg 51 | Telephone & Email | Hydropack | Koppen & Lethem | |

| 2712 PB Zoetermeer | +31(0)88 091 2811 | Vapo | GDM | |

| The Netherlands | sales.mechatest@vydraulics.com |