Liquid Sample Bottles

Sample bottles for liquid sampling

The liquid sample bottles, receivers or containers come in a variety of shapes, sizes, and materials. Select the proper container based on the product to be sampled to ensure that there will be no interaction between the product sampled and the container that would affect the integrity of either.

The sample receiver or container should be designed to facilitate the homogenisation of the sample in the laboratory so that a representative sub-sample may be drawn from it. All volatile samples of petroleum and petroleum products shall be protected from evaporation. Liquid samples with low vapor pressure will be mostly sampled in glass sample bottles with a cap with septa. Most used are typical Dopak bottles with PP28 and PP36 thread and cap or the laboratory bottles Duran types with GL32 and GL45 thread and cap.

- Process pressure < 8 barg

- Vapor pressure < 0.7 barg

- High pressure application > 8 barg suitable with Fixed Volume Sampler Type.

- Materials: Glass (clear, amber, cobalt blue or vinyl coated), PTFE, PFA, Polypropylene, LDPE, Aluminium, Stainless Steel

- Bottle types: Schott Duran with GL32 and GL45 thread, Dopak, ExxonMobil (other client bottles on request)

- Bottle Volumes: 2 mL, 10 mL, 25 mL, 50 mL, 100 mL, 250 mL, 500 mL, 1000 mL (other volumes on request)

- Hot or Cold samples can be collected in insulated bottles.

- All these bottle types are with screw cap and septa.

The Sample containers come in a variety of shapes, sizes, and materials. Select the proper container based on the product to be sampled to ensure that there will be no interaction between the product sampled and the container that would affect the integrity of either. The sample receiver should be designed to facilitate the homogenisation of the sample in the laboratory so that a representative sub-sample may be drawn from it. All volatile samples of petroleum and petroleum products shall be protected from evaporation.

Glass bottles are suitable for low pressure sample test and storage requirements. Clear glass bottles can be easily examined visually for cleanliness, and allow for visual inspection of the sample for haze (cloudiness), discoloration, free water, and solid impurities.

Glass bottles are used for the collection acids, caustic products, hydrocarbons, aromatics and water.

The amber (brown) glass bottle affords some protection to the samples when light may affect the test results.

Plastic Bottles in general are made of suitable material may be used for the handling and storage of caustic products, diesel oil, fuel oil, lubricating oil and water.

Plastic bottles should not be used for gasoline, aviation jet fuel, kerosene, crude oil, white spirit, medicinal white oil, or other petroleum products unless testing indicates there is no problem with solubility, contamination, or loss of light components. In no circumstances shall nonlinear (conventional) polyethylene containers be used to store samples of liquid hydrocarbons.

When sampling from a flowing pipeline, electrical continuity between the pipeline and the sample container via the connecting pipework can occur. Do not use plastic containers since they are non-conductive and will not dissipate static electricity.

- Single phase liquid samples

- Toxic liquid samples

- Dangerous liquid samples

- Volatile liquid samples

- Mostly refined (commercial) gas oil, diesel oil,fuels, lubricating oil

- Water / condensate samples (tap, brackish, saline, demi)

- ASTM D 4057

- ASTM D1265-05

- NACE MR0175 or MR0103

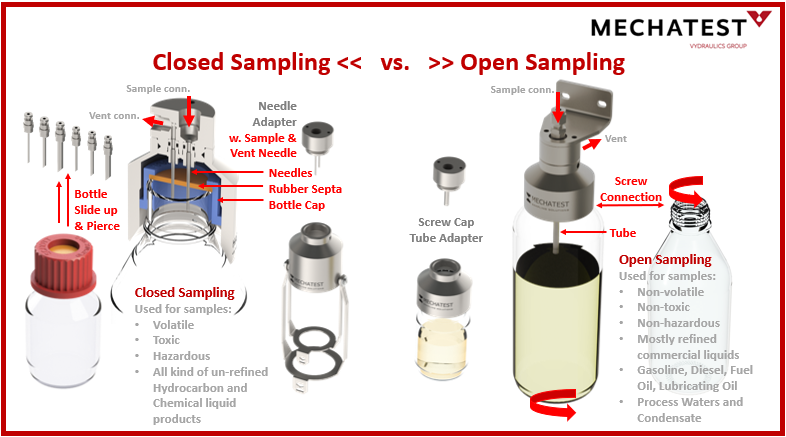

For Closed Loop Sampling

Closed loop sampling is used in case you need zero emission, safe for your health & environment, no pollution and prevent emission damage claims.

For use with "closed" bottles in combination with caps with hole and suitable for use with rubber septa. The sample system is for this type of sampling a device with sample/vent needles and a sample valve.

For Open Sampling

For use with "open" bottles in combination with "closed" caps.

The sample system is for this type of sampling a simple device with only a sample tube and sample valve or a screw bottle adapter, see below picture.

Plastic PP Caps with hole for Duran type glass borosilicate sample bottles GL32 and GL45

Aluminium Caps with hole for standard type glass sample bottles with cap size PP28 mm or PP36 mm

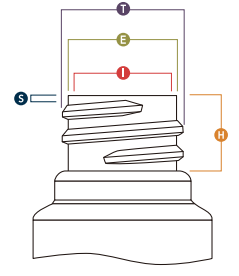

“E” DIMENSION – The outside diameter of the neck. The difference between the “E” and “T” dimensions divided by two determines the thread depth.

“I” DIMENSION – The inner diameter of the bottle neck. Specifications require a minimum “I” to allow sufficient clearance for filling tubes. Linerless closures, with a plug or land seal, and dispensing plugs and fitments require a controlled “I” dimension for a proper fit.

“S” DIMENSION – Measured from the top of the finish to the top edge of the first thread. The “S” dimension is the key factor that determines the orientation of the closure to the bottle and the amount of thread engagement between the bottle and cap.

“H” DIMENSION – The height of the neck finish. Measured from the top of the neck to the point where the diameter “T”, extended down, intersects the shoulder.

Typical sampling bottles neck / cap size (GL32, GL45, PP28 mm or PP36 mm) are suitable to use in combination with rubber or plastic kind of septa's.

Different Materials:

- Clear glass sample bottles

- Amber glass sample bottles

- Borosilicate glass sample bottles

- Polyethylene (PP) sample bottles

- Polypropylene (PE) sample bottles

- LDPE sample bottles = Low-density polyethylene (press to see more info @ wikipedia)

- HDPE sample bottles = High-density polyethylene (press to see more info @ wikipedia)

- PET sample bottles = Polyethylene terephthalate (press to see more info @ wikipedia)

- Teflon (PTFE) sample bottles are very good chemical resistance but disadvantage they are not clear and the volume height will be not visible.

- Most plastic sample bottles like LDPE, HDPE, PET, PP, PE are transparent and have also good chemical resistance.

Be part of the best solution, it all starts with you!

We make sampling solutions helping to protect the environment now and for future generations, together we can make a difference.

| Doedijns - Mechatest Sampling Solutions | Vydraulics Group | Vremac | Sypack | |

| Bleiswijkseweg 51 | Telephone & Email | Hydropack | Koppen & Lethem | |

| 2712 PB Zoetermeer | +31(0)88 091 2811 | Vapo | GDM | |

| The Netherlands | sales.mechatest@vydraulics.com |