Piston valve liquid samplers

Sampling of liquids by piston type valves

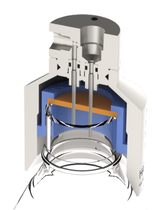

MBS-C

The Mechatest piston valve liquid samplers are the safe and efficient solution for pipeline and storage tank sampling also for high viscosity liquid samples the better choice!

The Mechatest piston valves are a perfect solution for liquid sampling from tanks, containers, pipeline, reactors and mixers, to take representative samples of liquids with higher viscosity by

using a piston valve, the entire line diameter can be cleared by the return of the piston. Sample dosing and filling of the sample bottle is made possible and regulated with a crank or hand

wheel, in contrast to a ball valve.

- Sample volumes 25, 50, 100, 250, 500 and 1000 ml (other on request)

- Max. Process Pressure 8 barg (116 psig)

- Max. Vapor Pressure 0.7 barg (10 psig)

- Safe (sampling) Process Temperature 60°C (140°F)

- Wetted Materials 316SS (other exotic materials on request)

- Replaceable Needle assemblies for Process and Vent needle, independent to choose in smaller or larger sizes. Needles made of small bore full hard temper tubing SS316, standard with very sharp Lancet style pointer, automated machined for long lifetime.

- Replaceable seats for the needles PTFE, (Viton or Kalrez) and in a width range of other materials available.

- Replaceable bottle holder makes the sampler very flexible, possibility to change later from bottle volume.

- Bottle holders are designed for GL32 and GL45 thread bottles (Duran/Fisher) with screw cap and septum in volumes of (25) 50, 100, 250, 500, (750) and 1000 ml.

- Bottle adapters also for Dopak bottles.

The big advantage of piston type valve sampling is the direct into the wall mounting principle, the sample is directly take of the inside tank, container, pipeline, reactors or mixer. We have improved our sampling systems for liquids by:

Creating closed loop systems which provide a safe, controlled environment, adding sample (needle or process) purge options, fixed volume sampling, which minimizes both waste and costs, simplifying designs, making the sampling of liquid and gas more efficient, proper discharge of excess liquid or gas prevents unwanted pressure build-up in the system.

These modern solutions simply regard the sampling systems themselves. Our worldwide reputation rests on the combination of excellent systems, and professional services by our team of specialists.

- Most innovative liquid bottle sampler solution on the market

- Modular and with a dozen of interchangeable options

- Closed Loop and Emission Free Sampling

- Safer for the operator and environment, prevent pollution

- Safer for the sample and safe sample

- Easy in operation and Low maintenance

- Option for second bottle retaining clip and use the sampler with two kind of bottle volumes (eg. bottle waste sample)

- Spring Return Handles available for Swagelok, Fitok and Hoke ball-valves.

- Options: Spring return handle on sample valve, panel-mounted and protection cabinets with heater, floor-stands, special elastomers on request, all kind of process connections, sample coolers

- Single phase liquid samples

- Toxic liquid samples

- Dangerous liquid samples

- Volatile liquid samples

- Mostly refined (commercial) gas oil, diesel oil,fuels, lubricating oil

- Water / condensate samples (tap, brackish, saline, demi)

- All samplers can comply with NACE MR-01-75 / MR-01-03 standards, for sour liquid sample applications.

- Acid samples • Amine samples • Alcohols • Aromatics • Benzene • Bio-fuel • Brine Water • Chemical mixture • Cumene • DCE (DiChloorEthaan) • Glycol • Gasoline • Hydrocarbons • Ketone • Kerosene • Naphtha • Paraffins • Solvents • Toluene • Xylene • etc.

- Safety sleeve around bottle (SS316 or POM)

- Spring return handles on valves

- Safety relief devices for overpressure protection

- Lockable handles

- Activated carbon filters on the venting outlet

- On mounting plate or in protection enclosures

- Drain or drip trays with flange connections

- Connection types and sizes

- Various materials

Enjoy the full benefits of an experienced team of passionate professionals

Mechatest employees possess decades of experience and knowledge. All of which is at your disposal when your sampling system needs adaptations, maintenance or repairs. Our staff has high-tech equipment at their disposal, thus increasing their efficiency even more. We are even capable of designing and manufacturing in accordance with foreign codes and standards.

Start improving by sampling process today

Why wait any longer? Improvement starts today if you pick up the phone and call us at +31 (0)15 – 310 51 83. Our staff provides you with all the information you need to make an informed decision and choose the best sampling systems for liquid or liquefied gas.

Also view

schramm polyester cabinets | sentry sample cooler | spot sampling

Contact us

Be part of the best solution, it all starts with you!

We make sampling solutions helping to protect the environment now and for future generations, together we can make a difference.

| Doedijns - Mechatest Sampling Solutions | Vydraulics Group | Vremac | Sypack | |

| Bleiswijkseweg 51 | Telephone & Email | Hydropack | Koppen & Lethem | |

| 2712 PB Zoetermeer | +31(0)88 091 2811 | Vapo | GDM | |

| The Netherlands | sales.mechatest@vydraulics.com |