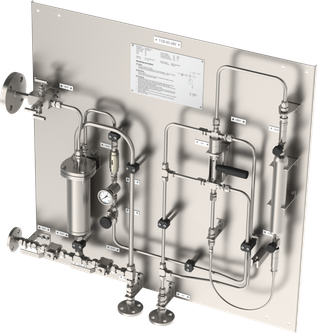

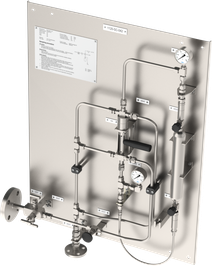

DUPLEX samplE CONNECTIONS

Mechatest delivers Duplex Stainless Steel (DSS) sample connections who are operator safe, closed loop and emission free.

Duplex Stainless Steel (DSS) S31803 Sample connections are gas sampling or liquid sampling systems connected to the process pipeline, a vessel, reactor, tank or loading arm. Sample connections in Duplex Stainless Steel (DSS) can take representative gas, crude oil, process water or other HC liquid samples under process conditions.

Hot samples can be cooled down, we provide sample coolers on the sample connection system, a total solution for hot gas or hot liquid samples.

The Mechatest Duplex Stainless Steel (DSS) sample connections allows for sampling in a safe and controlled environment. To take under high pressure liquid or gas samples the

conventional way is not only inefficient, but in the case of this dangerous media, humans and the environment are subjected to high safety risks, the Mechatest Duplex Stainless Steel (DSS) sample

connections are the safe and efficient solution for sampling under high process pipeline pressure and temperature. The Duplex Stainless Steel

(S31803) sample connections for gas or LPG sampling are based on gas cylinder sampling principle, the sample connections for liquid hydrocarbon products are based on glass sample bottles,

also called "dopak" bottles, both systems a perfect solution for sampling from tanks, containers, pipeline and reactors, to take representative samples in high pressure gas, crude oil, process

water or other HC liquid applications.

SAFE GAS or LIQUID SAMPLING - DUPLEX SAMPLE CONNECTIONS

Protecting both the operator and the equipment is the most important consideration when developing Duplex Stainless Steel (S31803) sample connection systems. First of all, sample connection in Duplex must increasing safety is a matter of simplicity. The easier the system is to operate, the smaller the chance of accidents gets. At Mechatest, we make sure that our Duplex sample connection are easy to operate by using single levers, easy-to-read pressure gauges, and a simplified system operation and for replacing parts. While taking the sample, excess emissions are redirected back into the system, thus preventing the built up of pressure in the sample connection.

We design and manufacture sample connection system according to your requirements

We know how important representative liquid or gas sampling is in the petrochemical industry. Therefore, each Duplex Stainless Steel (DSS) system can be tailored specifically to your needs and requirements. Inquire about the possibilities by calling at +31 (0)15 – 310 51 83.

The Mechatest Duplex sample collection assembly shall be designed with flange connections to suit the Process conditions and Environmental conditions. It shall be inherently safe to allow the operator to take sample and shall shield the operator from contact with the material being sampled. It shall be designed so that none of the sample’s analytical properties are altered between the sample take off and sample assembly. The Mechatest Duplex Sample connections assembly shall be rugged in design and is well proven in many petrochemical plant applications.

GENERAL DUPLEX STAINLESS STEEL INFORMATION

SAF 2205 is the most widely used duplex (ferritic/austenitic) stainless steel grade. It finds applications due to both excellent corrosion resistance and high strength. The standard duplex S31803 composition has over the years been refined by many steel suppliers, and the resulting restricted composition range was endorsed as UNS S32205 in 1996. Duplex S32205 gives better guaranteed corrosion resistance, but for much of the Duplex S31803 currently produced also complies with Duplex S32205. 2205 is not generally suitable for use at temperatures above 300ºC as it suffers from precipitation of brittle micro constituents, nor below -50ºC because of its ductile-to-brittle-transition.

DUPLEX SAMPLING APPLICATIONS

- Chemical processing, transport and storage

- Oil and Gas exploration and processing equipment

- Marine and other high chloride environments

- Pulp and paper digesters, liquor tanks and paper machines

DUPLEX CORROSION RESISTANCE

Excellent general corrosion resistance; superior to Grade 316 in most environments. Excellent resistance to localized corrosion including intergranular, pitting and crevice corrosion; the CPT of 2205 is generally at least 35ºC. The grade is also resistant to chloride stress corrosion cracking (SCC) at temperatures of up to about 150ºC. Grade 2205 will often perform well in environments which cause premature failure of austenitic grades. It has better resistance to sea water then Grade 316.

Contact us

Be part of the best solution, it all starts with you!

We make sampling solutions helping to protect the environment now and for future generations, together we can make a difference.

| Doedijns - Mechatest Sampling Solutions | Vydraulics Group | Vremac | Sypack | |

| Bleiswijkseweg 51 | Telephone & Email | Hydropack | Koppen & Lethem | |

| 2712 PB Zoetermeer | +31(0)88 091 2811 | Vapo | GDM | |

| The Netherlands | sales.mechatest@vydraulics.com |