Inline Flow Thru Liquid Sampler

Inline samplers for liquid sampling

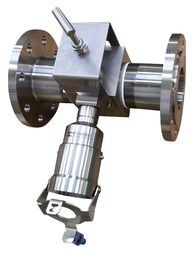

MBS-A7

Mechatest Inline sampling solutions - Flow Thru Liquid Sampler typical for pipeline and loading arm sampling. The inline flow thru sampling system consists of a full flow process diameter sample valve that allows for continuous flow through a pipeline.

Easy to install and operate, the sample flows into the sample bottle by opening a needle valve. The inline flow thru sampler can be used in a lot of applications but mostly mounted into piping

systems, this type of sampler is the best solution for loading arm sampling.

Mechatest offers a broad line of flow thru liquid sampling solutions, all available in a wide range of materials and fully compatible with the requirements of the Oil & Gas, Petro-Chemical and Chemical industries.

- Sample volumes 50, 100, 250, 500 and 1000 ml (other on request)

- Max. Process Pressure 8 barg (116 psig)

- Max. Vapor Pressure 0.7 barg (10 psig)

- Safe (sampling) Process Temperature 60°C (140°F)

- Made from forging 316/316L, Duplex (other on request)

- Sample valve NPT thread or flange connection 1/2", 1", 1.5" and 2"

- Wide variety of sealing materials; PTFE, Grafoil®, Viton, Kalrez, NBR, EPDM

- All samplers can comply with NACE MR-01-75 / MR-01-03 standards, for sour applications

The flow thru sampling system consists of a full flow process diameter sample valve that allows for continuous flow through a pipe line. Against the competition the Mechatest flow thru sampler body and valve is made from forging 316/316L bar material or higher grade Alloy with the advantage that both mechanical properties and corrosion resistance are much higher to those of the “equivalent” wrought grades.

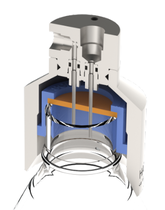

The rising stem sample valve allows the operator to control the flow of the sample being dispensed into the sample bottle. Rising stem needle valve with Ceramic stem ball tip Al2O3, superior hardness prevents deformation of the sealing tip and wear, significantly increasing the lifetime of the product for isolation purposes. This system can be used for medium pressures, temperatures and high viscous fluids where a continuous flow loop is needed. This flow thru sample valve is mostly combined with our ECO Needle Sampler with glass bottle, the process pressure pushes the sample through the valve into the bottle via a sample needle. Optional with Process Needle Purge connection, zero dead volume is ensured.

- Replaceable Needle assemblies for Process and Vent needle, independent to choose in smaller or larger sizes.

- Bottle holders GL32 and GL45 thread bottles with screw cap and septum (client bottles on request)

- Most innovative liquid bottle sampler solution on the market

- Modular and with a dozen of interchangeable options

- Closed Loop and emission free sampling

- Safer for the operator and environment, prevent pollution

- Safer for the sample and safe sample

- Easy in operation and Low maintenance

- Options: Panel-mounted and protection cabinets with heater

- Single phase liquid samples

- Toxic liquid samples

- Dangerous liquid samples

- Volatile liquid samples

- Mostly refined (commercial) gas oil, diesel oil,fuels, lubricating oil

- Water / condensate samples (tap, brackish, saline, demi)

- All samplers can comply with NACE MR-01-75 / MR-01-03 standards, for sour liquid sample applications.

- Acid samples • Amine samples • Alcohols • Aromatics • Benzene • Bio-fuel • Brine Water • Chemical mixture • Cumene • DCE (DiChloorEthaan) • Glycol • Gasoline • Hydrocarbons • Ketone • Kerosene • Naphtha • Paraffins • Solvents • Toluene • Xylene • etc.

- Safety sleeve around bottle (SS316 or POM)

- Spring return handles on valves

- Safety relief devices for overpressure protection

- Lockable handles

- Activated carbon filters on the venting outlet

- On mounting plate or in protection enclosures

- Drain or drip trays with flange connections

- Connection types and sizes

- Various materials

Enjoy the full benefits of an experienced team of passionate professionals

Mechatest employees possess decades of experience and knowledge. All of which is at your disposal when your sampling system needs adaptations, maintenance or repairs. Our staff has high-tech equipment at their disposal, thus increasing their efficiency even more. We are even capable of designing and manufacturing in accordance with foreign codes and standards.

Start improving by sampling process today

Why wait any longer? Improvement starts today if you pick up the phone and call us at +31 (0)15 – 310 51 83. Our staff provides you with all the information you need to make an informed decision and choose the best sampling systems for liquid or liquefied gas.

Also view

schramm polyester cabinets | bottle needle samplers | spot sampling

Be part of the best solution, it all starts with you!

We make sampling solutions helping to protect the environment now and for future generations, together we can make a difference.

| Doedijns - Mechatest Sampling Solutions | Vydraulics Group | Vremac | Sypack | |

| Bleiswijkseweg 51 | Telephone & Email | Hydropack | Koppen & Lethem | |

| 2712 PB Zoetermeer | +31(0)88 091 2811 | Vapo | GDM | |

| The Netherlands | sales.mechatest@vydraulics.com |